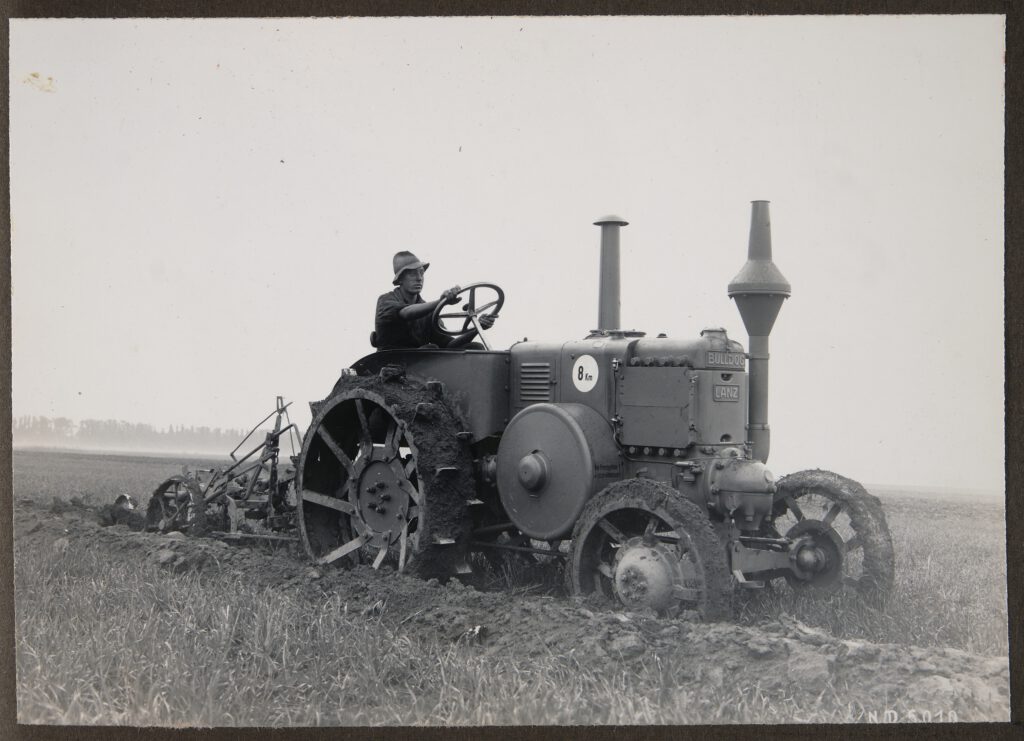

Lanz Bulldog tractor

[photos of Lanz Bulldog types]; s.n., n.d.

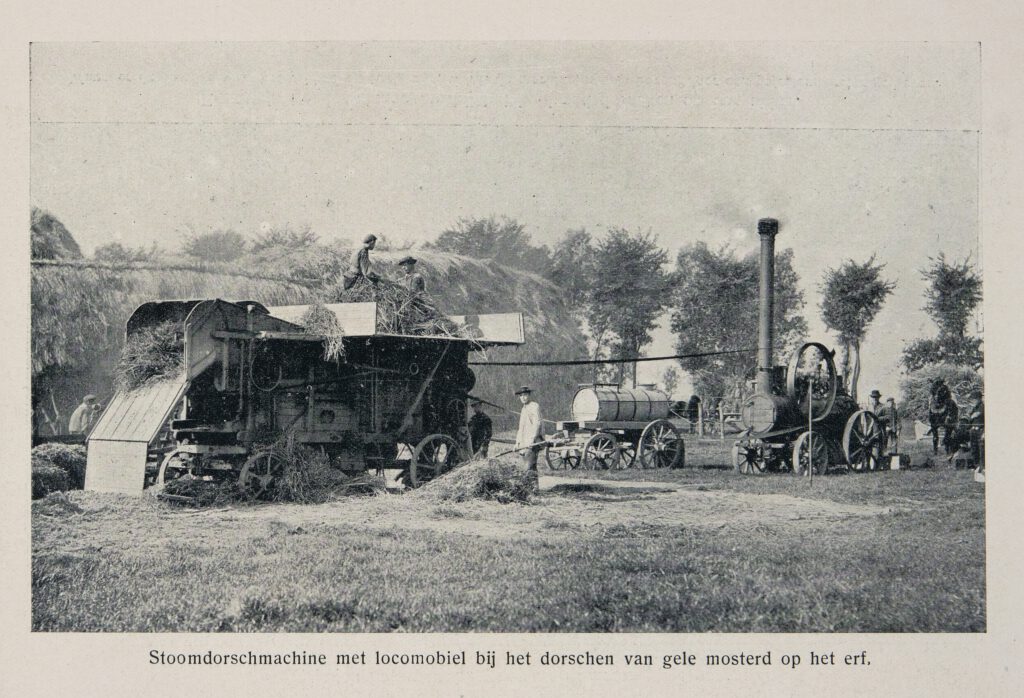

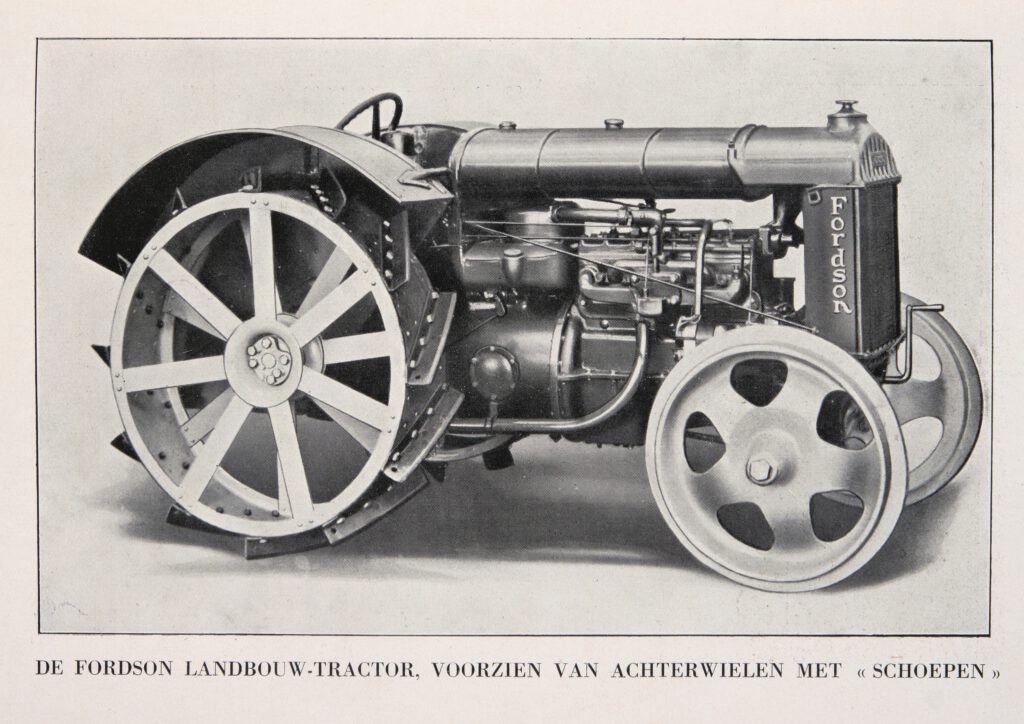

This undated photo book provides an overview of the different vehicles built by Lanz for various agricultural work. The first Lanz Bulldogs were equipped with a hot-bulb engine, a self-igniting combustion engine. It was not dependent on fuels like petroleum and diesel, but could also run on vegetable oil pressed from seeds or, for example, whale oil. It was also a very robust machine. In 1956, the John Deere company acquired the majority shareholding of Lanz, and the last tractor was produced under the name Lanz Bulldog in 1957. The company continued to operate under the name John Deere-Lanz AG from 1960. After 1967, the Lanz name disappeared completely and the company continued as John Deere.